Designing Successful Loop Systems

July 26, 2022

Printed Windscreen Brightens Elementary School Campuses

August 30, 2022Chain Link Fence Gate Fabrication Standards

This topic is one that is discussed often in the fence circles around the country. Many professional fence contractors fabricate their own gates in-house and many others purchase from a supplier or distributor. It is the personal decision of the companies what direction they wish to choose. There are also some that fabricate their residential gates but leave the commercial gate fabrications to suppliers or distributors. Again, the decision is yours as to how you decide to run your operation.

The following overview of chain link gate fabrication for me, started in my early 20’s while working with Jefcoat Fence Company, in Pearl, Mississippi. The owner, Mr. Jere Jefcoat sent me to Automatic Gates in Memphis, Tennessee to spend a few days with Phillip Doyle for some gate operator insights and training and he introduced me to welding gates. The “cheat sheet” as he called it, for proper cuts and notching was scratched on a piece of paper and hung on a nail in the fabrication shop. This “cheat sheet” had so many marks and changes on it, it was hard to determine what measurement was the correct one. But Phillip knew this chart like the back of his hand and quickly got me up to speed on the “how to” building a chain link gate.

With a wire welder, he had me welding 1 3/8’ x .047 tubing and I was blowing holes in it like crazy. He taught me the correct techniques such as direction of the wire flow, moving the welding wand in a smooth manner and I got the hang of it quickly. Now, let’s be very clear, I was NOT a certified welder by any means, but I could weld and build a structurally sound good gate. It provided me the knowledge to establish our own shop for Jefcoat Fence and control our gate fabrication schedule in-house.

I share all this to say, if I can learn how to weld and how to set up a welding fabrication shop, so can you. Many companies have made the decision to build their gates in-house to maintain better control of their schedules and in most cases, add profitability to their operation.

So, lets discuss the basics needs for a proper shop and fabrication set up. Of course, we must always make sure we have proper welding protective equipment such as safety glasses, welding jackets, hood, gloves and always a good pair of leather boots. Next is our shop tools that will include some type of pipe cutter and pipe notcher and a good wire welder. Many use a rod welder and if that is your preference, keep on using it, but for heavy production and efficient welding, a wire welder will your best choice.

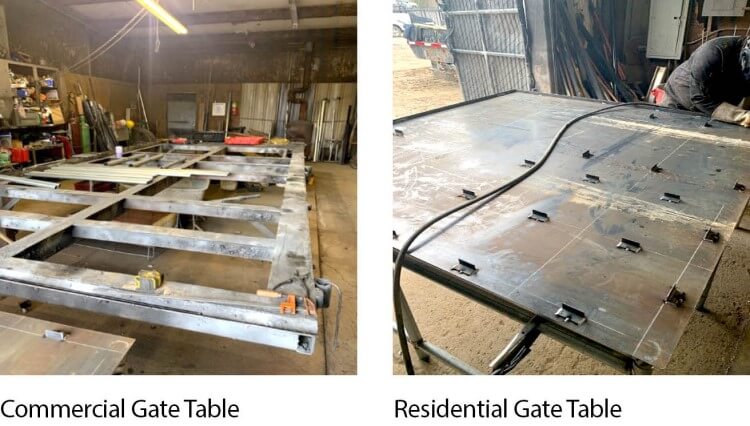

Once you have established the necessary shop setup and tools, companies should consider a gate fabrication table of some type. Gates have been welded and I have personally witnessed many gates fabricated on the floor of the shop and this practice works, but will eventually wear on the fabricator and it is best to build a fabrication table of some type.

The following are examples of both commercial and residential gate tables:

Regardless of how you decide to build a table, it will add efficiency to your fabrication and if you are doing a lot of chain link work, a gate fabrication table will pay for itself in just a few gate builds. Invest in a well-designed and heavy duty table and it will be there for the long haul.

The following is an example of best practices for fabricating a residential gate:

Residential Single Gates (1 3/8” tubing framework) Opening less 6” for cross piece cuts (2 required; NBE) Place cross pieces 1” from top of uprights Place bottom cross piece ¼” from bottom of upright Height less 2 ½” for upright piece cuts (2 required) Add horizontal (cross) brace for all gates over 4’ height (1 required; NBE) Add 3/8” truss rods for all gate panels over 10’ width EXAMPLE: 42” opening X 48” high // 36” cross piece cuts and 45 ½” upright cuts

The following is an example of the best practices for fabricating a commercial gate:

Commercial Single Gates (1 5/8” framework any weight) Opening less 6 1/2” for cross piece cuts (2 required; NBE) Height less 3” for latch side upright piece cuts (1 required) Height less 1” for hinge side upright piece cuts (1 required) Add horizontal (cross) brace for all gates over 4’ height (1 required; NBE) Add 3/8” truss rods for all single gates over 10’ width Add 13” to upright cuts for bard wire EXAMPLE: 42” opening X 72” high // 35 1/2” cross piece cuts and 71” hinge upright cut, 69” latch upright cut.

The following is an example of best practices for fabricating a commercial cantilever gate. This style has a compression brace, but many fence professionals use a retention and works well as a best practice as well.

Cantilever Gates Cross pieces (2 ½” SCH 40)= Gate Opening + half of opening + 1’ for overall gate length Height of fence less 10 ½” for uprights (2” SCH 40, NBE) Diagonal Braces cut to fit (1 5/8” SCH 40, NTF) Barb Wire Brackets, 4” offset (NBE) / 18” upright (1 5/8” SCH 40) Welded from top of gate on the 2” uprights, right below the 2 ½” cross piece NOTE: 1) Uprights will not exceed 5’ spacing 2) Fabric will cover full length of gate 3) Welded truss rods, tension wire at top/bottom for fabric attachment with hog rings Example: 20’ opening x 72” high (20’ + 10’ + 1’ = 31’ o/a length) Cross pieces 2 ½’ SCH 40 x 31’ (2 required) Upright cut 61 ½” x 2” SCH 40 (7 required, NBE) Diagonal Brace (6 required, NTF)

Fence companies have their own “best practices” for fabricating gates to accommodate their needs and the results are the same: a more productive and efficient company to add profitability to the operation. If you are interested in establishing your own gate fabrication shop or interested in receiving a complete Chain Link Gate Fabrication “best practice” outline, please email info@fenceconsultinggroup.com.

Tony Thornton is a 45+ year veteran of the fence industry and is a subject matter expert in all areas of fence and gate automation. His passion is to elevate and promote the fence industry in a professional manner and provides consulting services to support fence industry owners in understanding how to implement effective procedures into their operation and maximize their profitability.

Thornton Fence Consulting Group 4261 East University Drive, PMB #30-108 Prosper, Texas, 75078 Phone: 972-533-3658 | Email: info@fenceconsultinggroup.com | Website: www.fenceconsultinggroup.com