The Rise of Ornamental Aluminum Fence

September 30, 2022

Wood Fence Trends

November 1, 2022Top of the Chain

with Bill Peterson PRESIDENT, RICHARD’S FENCE

Bill Peterson’s father, Richard, founded Richard’s Fence in 1968, installing fence for Montgomery Wards and Sears. Bill grew up in the industry, working for his father at a young age and learning the intangible qualities that come with it such as dependability, honesty, integrity, and the value of a good reputation. He was named vice president in 1990.

Located in Akron, Ohio, the company currently has 35 employees. Bill’s brother, Eric, is the vice president and runs the manufacturing operations. The family legacy continues with Bill’s son, Drew, and daughter, Jacqui, working in the business. Read on to learn how they balance it all.

YOU WORKED FOR YOUR FATHER’S COMPANY SINCE AGE 12. WHAT DID YOU LEARN IN YOUR TEEN YEARS WORKING THERE?

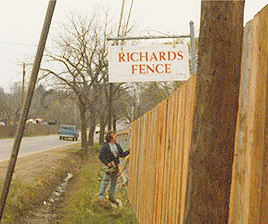

Dick’s sons, Bill and Eric Peterson, acquiring fencing

skills in 1978.

Dick’s sons, Bill and Eric Peterson, acquiring fencing skills in 1978.

Work became a habit, and it was something that you just did. I would compare it to families that grew up on farms and had chores that were expected to be done. My dad taught me to drive a stick shift truck at age 13. I would move the delivery truck around the yard, after hours, to help him load the truck for tomorrow’s deliveries. At that time, the fence company was next to our house, so it was always a part of our lives.

School was important so I did not work during that time, but my standing summer job was at the fence company; even so, we always had plenty of time to have fun. I spent many summers riding go-carts or minibikes that my dad built. He was always building something, sometimes a pipe coater, sometimes a go-cart.

LATER, DURING COLLEGE, YOU INSTALLED FENCES. WHAT DID YOU LEARN DURING THAT TIME?

Dick Peterson, founder of Richard’s Fence, installing a wood fence in front of his company in 1978.

Installing fence was an invaluable experience for learning that part of the fence industry. Since my college class schedule was too erratic to work at the fence company, I convinced a friend that we could make good money installing fence. My dad had taught me the basics and always had great advice for problems or challenges we might experience. In fact, my dad started in the fence industry much the same way, when a friend of his asked him to help install fence part-time for Sears and Montgomery Ward.

Those college years taught me how all the parts form a fence structure and to appreciate the challenges the installers face each day. Everything from tough digging, tough customers, and their angry dogs.

I also learned that nothing is more frustrating than driving an hour to a job only to find that the distributor gave you the wrong parts and you are unable to finish the job. I stress to our shipping department that sending the right parts is very important, and if something doesn’t look correct, don’t be afraid to ask the customer.

My favorite installation story is when we were asked by another company to replace a double drive gate at the National Guard Armory in Canton, Ohio. It was a rush job that had to be installed on a Saturday so a desperate installation company asked a couple of college kids if we could do it. We showed up to the Armory on time with the new gates, but the skeptical sergeant couldn’t find the key to open the damaged gate. “Good thing we are not at war,” I said under my breath. The sergeant was shocked by how easily we opened the gate by taking off the hinges and dropping the gate! We had the new ones up in thirty minutes. That sergeant was impressed by how we solved the problem.

DID YOU ALWAYS ENVISION YOURSELF WORKING AT RICHARD’S FENCE, OR DID YOU HAVE OTHER ASPIRATIONS?

Although I did some different jobs when I was younger (busboy, farming, installer), I always felt that I was to work in our family business.

WHAT COLLEGE DID YOU ATTEND?

I graduated from the University of Akron with a Bachelor of Science in both marketing and management. I also take continuing executive education courses with the Weatherhead School of Business at Case Western Reserve. I think it is important to keep learning and challenge yourself. It can be easy to fall into a rut and keep doing the same things without improvement.

YOUR INVOLVEMENT IN THE LOCAL AND NATIONAL AMERICAN FENCE ASSOCIATION IS REMARKABLE. WHAT MOTIVATED YOU TO BECOME INVOLVED AND WHAT KEEPS YOU ACTIVE THERE?

Dick Peterson, my father, along with Tom Polen, Dave Richards, Mike Kalinich, Sr., and Mike Goldstein started the Northern Ohio chapter of the AFA back in the late 70’s/early 80’s. When I graduated college in 1987, my father told me I need to attend the meetings. Four meetings later, they made me president of the chapter, mainly because I would show up and they were tired of passing the position back and forth.

During those years, the local chapters were more active. We would have eight meetings in addition to the golf outing, a table-top show, and usually a Christmas party. After about four years as president of the local chapter, I was appointed as a director of the national AFA by Michael Kalinich, who was president of the national AFA at that time. I ended up serving a second term as director and was able to serve on the AFA Show Committee for three shows in the 90’s. I continue to attend local chapter events.

WHAT IS YOUR ROLE WITH THE TECHNICAL SUPPORT TEAM OF THE CHAIN LINK FENCE MANUFACTURERS INSTITUTE?

My father joined the CLFMI in 1989 and attended the meetings. About 12 years ago, I became the company representative and took over for my father and quickly joined the technical support team.

I learned a lot from the people on that committee (Bill Ullrich, Tom Stanek, Chuck Naegele, Steve Peters, and many others). I was honored to eventually be appointed chairman of the committee for four years. I am currently the secretary/treasurer of the CLFMI and I still serve as a member of the technical support team.

YOUR BROTHER, ERIC, IS THE VICE PRESIDENT AND RUNS THE MANUFACTURING OPERATIOS. HE AND YOUR FATHER HAVE DEVELOPED NEW AND MORE EFFICIENT WAYS OF PRODUCING WIRE AND FENCE FABRIC. HOW DO THEY COLLABORATE?

My dad and brother designed and built our strand wire coating line, our fence weaving machines, our minimesh weaving machines, pipe coating line, and our fitting coating line. They both have the gift of looking at a machine process and making it more efficient and increasing its production. They can also fix just about anything. They are passing this information down to my son, Drew, who is comfortable with the new technologies that are changing rapidly. I am involved with the business side and ensure we are efficient in all areas of operation.

WHAT SETS RICHARD’S FENCE APART FROM OTHER FENCING MANUFACTURING COMPANIES?

Thanks to the ingenuity of my brother and my father, we’re always creating new products. We’re very hands on, as a lot of true family businesses are. My father has officially retired, but still comes in everyday, but with Eric, and my son, Drew, and my daughter, Jacqui, and myself working and caring about the business, we’re confident in our future. We also have a very talented staff that we feel are extended family. People can tell if you care about them, and then they tend to care about doing a good job.

WHAT ADVICE HAVE YOU RECEIVED THAT MADE AN IMPACT ON YOU?

My father has and continues to give great advice. He impressed on me that a manager needs to be present and involved with what is really going on in the company. He would tell me to not be complacent and to strive to make things better. He would also say, “Don’t sell too cheap!” which was his way of telling me to always keep an eye on the margins. Sales do not mean a thing without profits to keep everything running.

HOW DO YOU ENVISION THE FUTURE OF THE COMPANY IN 10 TO 15 YEARS?

I feel we are very solid as a business. My father is a unique person who was very good at both the management and operations part and the manufacturing part and built a successful business with a lot of hard work. My brother and I tend to gravitate to our strong suits: Eric with manufacturing operations and myself with the business operation. We work well together. Our third generation, Jacqui and Drew, are very capable and are learning all parts of the business. They have the skills to take the company into the future.