On the Fenc: New Research Taps Rancher Expertise on Living With Carnivores

December 27, 2022

Top of the Chain – Shane Miller

January 24, 2023Chain Link Fence, Tube and Fittings

Affordability, variety, durability and quick installation . . . these are just a few of the advantages of chain link fence. The companies providing the materials, fittings and tubing are continuously improving their craft. Check out some of the innovations and availability from these chain link experts.

Angling for a Better Notch

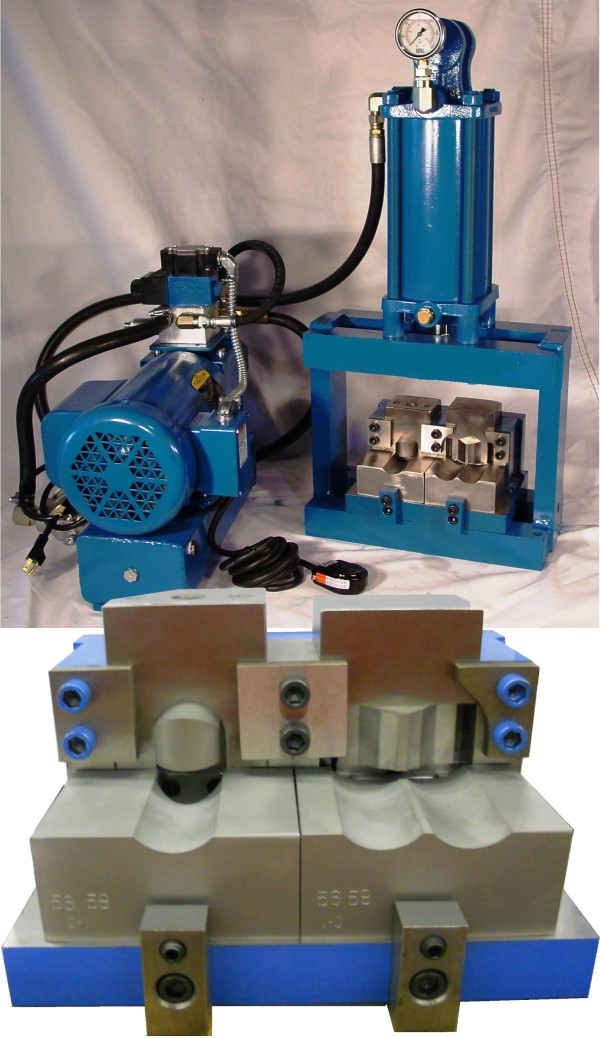

Many in the fencing industry are familiar with long-time industry partner Vogel Tool & Die. Their pipe notcher, invented in 1934 is a staple in many shops and is used worldwide.

While the original hand-operated process, known as the Arc-Fit method for notching a pipe end for a 90° joint is still in use today, other less-known Vogel tools can have a significant impact on improving manufacturing processes and helping a fencer’s bottom line.

One of those tools, according to Larry Siegal, sales manager with Vogel Tool & Die, is their Arc-Fit Angular pipe notching tool.

“Prior to Vogel’s invention, time-consuming grinding or torch cutting was the most common method to notch pipes or tubes to prepare for joining,” explains Siegal. “While the first tool that started the company over 80 years ago was for the most common 90° notch, pipes needing to be welded at other angles remained a challenge. We expanded our product line to include angular notching tools to resolve that issue. We consider this a ‘hidden gem’ of a tool because there is no other reliable way to produce the notch quickly and consistently.”

Vogel’s Arc-Fit Angular is often used for notching pipes for handrails or when a cross brace is needed for large chain link fence panels & gate. Siegal hears from many fencers who are still torch cutting or grinding the pipe end to create the angle, but this often results in a sloppy, inaccurate notch requiring additional welding work to attach. He explains that this means more time required for completion and less than professional looking results. “Our tool completes the notch in under 10 seconds and its consistent and correct each time. We hear back from so many customers who are thrilled at how quickly the tool works. Frankly, many are upset that they had not heard about our angled notching tools sooner,” Siegal says.

Vogel’s angled notching tools are dedicated to specific tube sizes and angles, but the housings can be reused when a different angle is required. Each tool is spring loaded for easy set-up. The notching process is fast and easy. A slug is produced, not chips, so no secondary handling for chip removal is required.

Siegal says Vogel also builds custom tools for specialized part applications, such as notching a tube to fit a different size tube or notching with an extra drain hole for gates that will be hot-dipped galvanized after welding. Vogel also offers a bench-top hydraulic press to power their Arc-Fit Angular tools and many other Vogel tools such as pressing metal pickets, piercing channel or tubing for horizontal rails of ornamental fences and more.

Vogel’s tube and pipe notchers are proudly American-made and in use worldwide. Learn more at www.vogeltool.com.

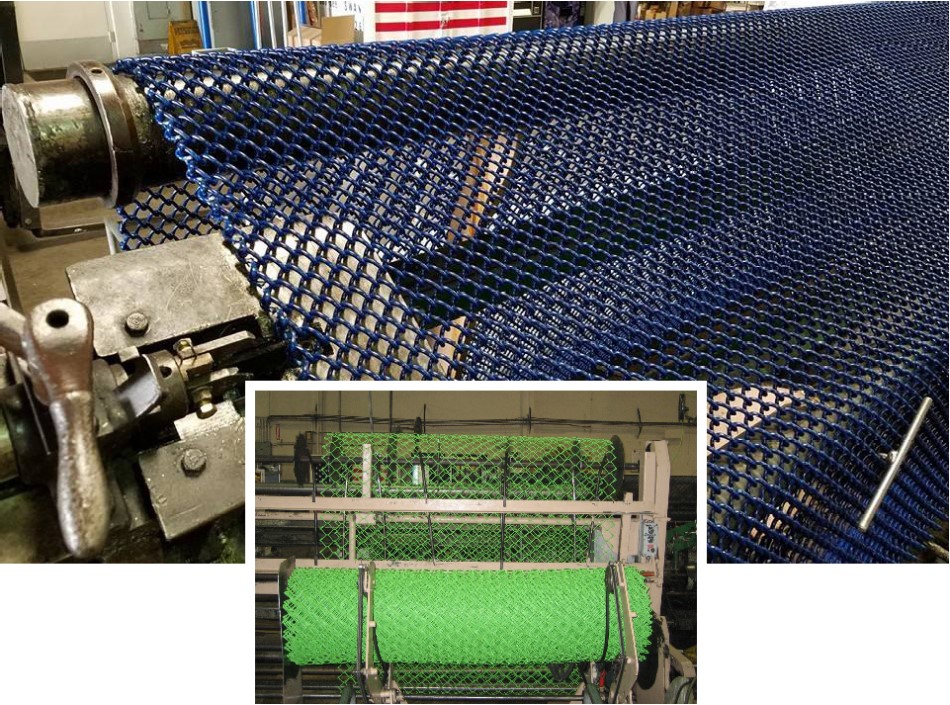

A Closer Look at Extruded Bonded and Fused Bonded PVC Coatings for Chain Link Fence

Vinyl coated chain link fence is an increasingly popular alternative to regular galvanized chain link. The added coating enhances the appearance of chain link, as well as providing corrosion resistance.

Originally a weaver of only galvanized chain link fabric, Swan Fence in Compton, California, now manufactures extruded bonded and fused bonded PVC, or polyvinyl chloride, coated chain link in a variety of colors and special sizes. According to Tracy Jakositz, with sales at Swan, there are different methods of applying the coatings and a wide variety of standards and specifications, such as gauge and mesh size, are available.

Jakositz explains that extruded bonded, often called “extruded and bonded,” features PVC that has been applied by pressure to a steel core wire. “Our extruding process is a pressurized application. The steel wire is coated with adhesive and then travels through the extruding machine, where the PVC, which starts in a plastic, hard state, is melted and compressed directly onto the heated adhesive under 5000 pounds of pressure to create a dense and impervious coating.”

Twelve different standard vinyl colors are available with the extruded bonded process at Swan Fence. The vinyl coating thickness is .015 - .025 inches at any point (22 mils).

Fused bonding is the process where PVC is thermally fused to a core steel wire to not only protect it, but also to create an outer layer with color. This process is an atmospheric or baked-on application. The steel core wire is heated, and then adhesive, or primer, is applied. The heated steel travels into a machine containing the PVC, which is in a very fine powder state. Air is blown into the machine, which causes the PVC powder to circulate. When the heated steel coated with adhesive comes in contact with the PVC, the PVC melts or fuses onto the surface.

“In other words, the fused bonding process literally bakes the PVC onto the wire,” says Jakositz. The PVC-coated wire is then woven into a chain link fence of various mesh sizes, heights, and colors. The vinyl coating thickness is .006 - .010 inches at any point (7 mils).

She adds that although the PVC-coating on fused bonded wire is thinner than extruded bonded wire, it is tougher and more resistant to moisture and peeling. Swan offers six standard colors and is also able to match any custom color with the fused bonded process.

Swan Fence specializes in custom heights, from 12” up to 50’, custom colors, and can weave a ¼” mesh up to a 2” mesh. Jakositz says their company has provided material for several of the CLFMI design award projects, many football stadiums that wanted to match their team colors, and most of the custom color designed freeway overpasses.

Learn more about Swan Fence’s products at www.swanfence.com.

Mesh Size Matters

Chain link is one of the most common types of commercial and residential fencing, and for good reason. They are typically simple to install, highly functional, cost-effective, and serve a variety of purposes.

The mesh, also called the fabric, of chain link fence is formed by weaving a series of spiral wires together to form a diamond pattern that is available in different sizes. Mesh size tells you how far apart the parallel wires are in the mesh. “That is another indication of how much steel is in the chain link; the smaller the diamond, the more steel is in the chain link fabric,” says Josie Borkholder, with Pine Creek Chainlink in Bremen Indiana. His company specializes in galvanized and vinyl chain link fence systems. “

To find the mesh size, he says to measure the diameter of the diagonal interior squares. A typical mesh size is 2 inches, which means the wire gauge size is 9 or 11. If the mesh measures 2.25 inches, then the gauge is typically 11.5, which is thinner. “The grid or mesh size you need depends on the purpose of your fence and consideration of the security risks and anticipated force your fence may need to withstand. As a general rule, the smaller the mesh size, the more durable is your fence as it has more metal. For example, industrial and high-security fencing requires a much smaller mesh size of .38 to .62 inches, to allow for a thicker gauge and smaller opening to prevent cutting and/or climbing. A residential size would be 2 to 2.38 inches. A midsize mesh of 1 inch to 1.75 inches is a good choice for enclosing sports fields.”

Borkholder adds that when it comes to mesh sizes, it’s important for contractors to both understand the variances in mesh sizes and make sure they are comparing the same type of product when they are looking at cost. “The price is what you pay; the value is what you get.”

He says one of their most popular options is GBW galvanized. “It doesn’t have the galvanized burrs on the fabric and is definitely safer for kids. It also stretches very nicely when installing.”

Pine Creek Chainlink offers 100-foot rolls of chain link fabric instead of just 50-foot rolls for large commercial jobs. They also recommend the EZ Hog Fence Stretchers. “These options save contractors time and improve efficiency, especially when facing staff shortages,” says Borkholder.

Learn more about Pine Creek Chainlink by calling (574) 301-5900.