Unlocking Success: Insights from the Mr. Fence Academy Retreat 2024

May 28, 2024

Top of the Chain with Karl Stinson

May 28, 2024Start-Up Stories

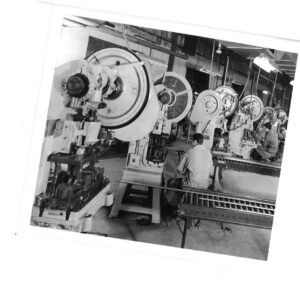

by Vogel Tool & Die

“Proudly Manufacturing Quality Tools in the USA for 90 Years”

It’s said that necessity is the mother of invention, and that cliché applies to the beginning of Vogel Tool & Die. Ninety years ago, Julius Vogel created a tool to speed up the process of attaching one end of a pipe to the side of another. His solution to a common production problem provided the foundation of a successful business that continues to strengthen its reputation for dependability across a wide range of industries.

“Prior to Mr. Vogel’s invention, time-consuming grinding or torch cutting was the most common method to notch pipes or tubes to prepare for joining,” explains Larry Siegal, sales manager with Vogel. “The resulting pipe ends were inconsistent, making the welding process to attach them trickier.”

Vogel’s invention, the Arc-Fit method, was granted a US patent in 1938. Based in Chicago, Vogel Tool & Die became an important supplier to the huge manufacturing hub in the region. Companies like Schwinn, Zenith, Motorola, and many others depended on Vogel tools. Growth was rapid and consistent, and the product line expanded over time to include tools to cut tubes, piercing, slotting, mitering and much more, all with the focus on the fabrication of tubular parts. “Our mission has always been to design tools that are dependable, easy to use, and that helped make manufacturing more efficient,” says Siegal.

He explains that the original Arc-Fit tool design has remained essentially unchanged. Today, the Arc-Fit hand operated pipe notching tool, along with power options, are available and are still considered a ‘hidden gem’ of a tool because there is no other reliable way to produce the notch quickly and consistently.

While changes have been made to streamline the production process and incorporate improved manufacturing technology, maintaining the core product’s design ensures backwards compatibility when a customer needs to replace a part. “We save our customers money by not building in the obsolescence that seems to be common practice with so many products these days,” says Siegal.

Vogel’s tube and pipe notchers remain one of the company’s most popular products and are in use worldwide. High production options include the Arc-Twin line of tools that will notch a tube or pipe end in one stroke. A newer, popular tool presses pickets from square tubing. “Prior to this tool, the typical ornamental fence had ornate tops, produced from a casting,” explains Siegal. “In addition to the expense, vandals would sometimes smash the tops. The pressed picket concept eliminates this risk and is a less expensive solution.”

The company was owned by four generations of the Vogel family until 2009, when it was acquired by Manor Tool & Manufacturing Company, another Chicago-area family business. Manor Tool & Manufacturing Company began as a tool and die shop in 1959 and grew to become a first-class metal stamping company manufacturing everything from musical to military components. The Vogel name was so well known that the new ownership never really considered rebranding the products. To this day, Siegal says customers will call up and instead of saying, “I need to replace my pipe notcher,” they say, “I finally wore out my Vogel.”

Vogel has two locations. The primary factory is in Addition, Illinois, and the parent company, Manor Tool & Manufacturing, has a large facility in nearby Schiller Park, giving them the flexibility to shift production based on workload.

If asked about a secret to their success and longevity over a century of challenges, one answer from Vogel management would be their team. They currently have 57 employees, many of whom have been with them for decades. “I have been with the company 30 years, the last 15 as sales manager,” says Siegal. “I was hired by the grandson of Julius Vogel. My story of long-term job satisfaction here is a common one among our team. General manager Rene Vega started 29 years ago as a tool designer. Shop foreman Tim Taylor joined Vogel at age 17 and is now celebrating his 40th year. Vogel’s president Thomas Simeone grew up in manufacturing and is the second-generation owner of Manor Tool and Manufacturing.”

Another key to Vogels success that might surprise many is the pride they take in not focusing on being necessarily cutting-edge. “Our Arc-Fit pipe notcher is certainly an old-school workhorse, but we know thousands of businesses have, and still, depend on it as a core part of their production,” says Siegal. “There’s something to be said about committing to doing what you do – and have done for decades – well, particularly when we are known for the legendary durability of our tools.”

Vogel continues to operate primarily as factory direct. “Our customers will tell you that when you deal with Vogel it’s still that wonderful small family-business feel,” says Siegal. “No one likes fighting their way through automated phone systems or having calls transferred over and over. When a customer calls Vogel, they talk to a person, and that person is typically me.”

The company looks forward to many more years of serving their customers, continuing to produce tools they rely on and that help them be successful. “So many in the fencing industry are small family businesses filled with wonderful hard-working dedicated people,” adds Siegal. “It’s an honor and privilege to have worked with so many and to be confident our tools help make their operations more efficient.”

1400 Press

Learn more at VogelTool.com.

Those on the outside may think owning and growing a business is glamorous. They see the current building, the staff, the equipment and the profits. What they don’t see are the startups. The small beginnings, the ever-present worry, the dreams and the everyday decisions that can either make it or break it.

Fence News honors those who put their hat in the self-employment ring and built their business one small step at a time.