Trex Launches New Trex Signature® X-Series™ Railing

August 29, 2024

5 Ways to Use Deck Colors and Patterns to Differentiate Outdoor Living Space Designs

September 26, 2024Safe Earth Drill Storage

How to Store Earth Drills Properly Throughout the Winter Months

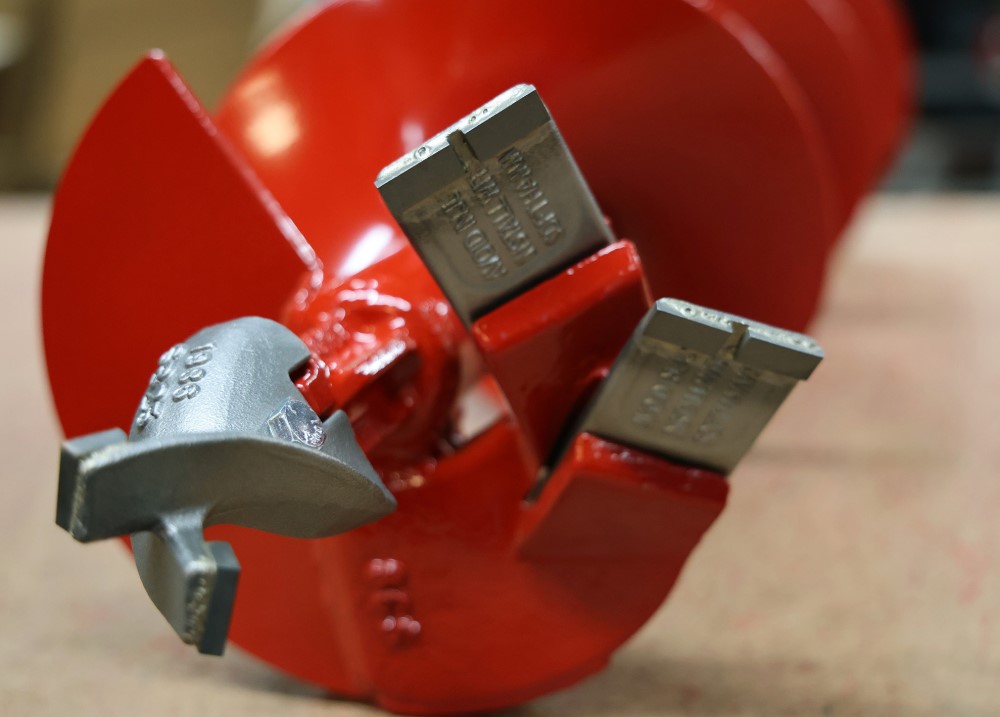

Most contractors that employ earth drills will experience an approximately three-to-four-month winter period in which the equipment is not being used. Before storing an earth drill for the season, Joe Haynes, president of Little Beaver, says it’s important to take some time to thoroughly examine the drill and ensure that all components are in working order.

He offers these simple steps that will help ensure the machine is ready to go in the spring.

Don’t leave blades dull or rounded since drilling with them can damage the flighting of the auger. Install new blades if they are replaceable or sharpen carbide blades.

Before storing a hydraulic earth drill, check for hose leaks or loose connections and look for any cuts or cracks that might be causing them.

Hydraulic Hibernation

To prepare a hydraulic model for storage, remove the shroud between the tank and the engine to inspect the coupling component. Make sure the rubber spider is not worn or missing pieces. Check for hose leaks or loose connections and look for any cuts or cracks that might be causing them. Additionally, lock the drive head into the “storage” position by pivoting the handle.

Don’t leave the drill out in the cold all winter. Hydraulic oil thickens as it becomes cold, which could damage the hydraulic system and the hoses. The hydraulic oil needs to be changed every three months or 100 hours of use, so it’s more efficient to simply drain the oil for the storage period; just don’t forget to replenish it in the spring. Use premium mineral oil with anti-wear and anti-foaming additives. If the drill does need to be used in frigid temperatures, use ISO VG 32-grade oil (46 for normal temperature operation and 68 in warmer climates).

Year-End Mechanical Maintenance

Routine maintenance during active drilling periods of the year keeps the drill primed for the most rugged applications. This includes inspecting, cleaning and lubricating applicable parts for every 30-40 hours of use. But when the drill’s hard work is done and it’s time for its seasonal slumber, ticking off some end-of-the-year checkboxes will make sure it’s ready to go next spring.

Look for rust on the push button connector and, if there is any, wipe it down with WD-40. Check out the throttle cable — there’s a good chance it will need to be taken apart to clean. If frayed, it should be replaced.

Ready for Spring

Some storage preparation steps apply to both hydraulic and mechanical units. There are a couple options for winterizing the gasoline-powered fuel system of mechanical or hydraulic drills. The simplest is to completely drain the gas tank. Another option is to add fuel stabilizer solution, which forms a protective layer by bonding with gasoline to prevent evaporation. It also stops the buildup of sticky resins that can destroy a carburetor and remains effective for up to one year.

Fuel stabilizer is recommended any time a gas engine, especially an older one, will be out of use for three weeks or more. Fill up the rest of the tank upon taking it out of storage, as this will diffuse the stabilizer. Nonethanol gasoline is best for this type of equipment, especially when putting it away for storage or filling up in the spring. Ethanol’s corrosive effects increase the longer the machine sits idle, and the blend doesn’t always mix well with stabilizer. Once this is done, grab a couple wrenches and tighten up all bolts, as they can become loose through the course of routine drilling and transportation.

Always store earth drills in a warm, dry space. Left to the elements in a high-moisture area, the steel will eventually develop rust. Make sure to keep them in a space that doesn’t get heavy foot traffic, so it won’t get knocked over or otherwise disturbed, especially if there is a chance of animals or small children being nearby.

Don’t leave the blades dull or rounded since drilling with them can damage the flighting of the auger. Install new blades if they are replaceable or sharpen carbide blades. Sharpen with a carbide bench grinding wheel tilted to a 5-7-degree relief angle. Clean the blades with warm, soapy water. Do not use a pressure washer, which is too abrasive and can cause damage.

“Properly storing earth drilling equipment will keep it running smoothly for many years to come,” adds Haynes. “For any maintenance questions, reference the owner’s manual, or work with a manufacturer to learn more about how to properly service the drill.”

Learn more at littlebeaver.com.